|

|

|||||||||||||||||||||||||||||||||||

|

Let’s hear about the failures (Note: I used a modern junker movement in my

experiment, having first stripped off the lacquer.) Yup, there have been some. When I first got my tumbler, I used only

crushed walnut shells. That wasn’t enough. It took nearly three days to achieve a

finish, and then, the residue on the parts had to be cleaned off. Next I thought I’d add some common

liquid soap and water. Wrong! This became watery slurry of the crushed

shells and left the brass a very deep brown.

Only Scotchbrite would take off the brown finish. Then I spoke with Jim Moss about

the situation. He advised against

anything with water because of the battery reaction (leading to corrosion)

between brass and steel. Eliminating

the water was a “no brainer”. Next I tried walnut shells and

chalk. I remembered that Jim Moss

advised that he made a paste of chalk and Stoddard’s solution to hand polish

clock parts. This change in media produced

a rather pleasing effect, but the tumbling time was still in “days”, not

“hours”. The crud residue was minimal,

but there was still finish work to be done. Then I introduced stainless steel

Jeweler’s mix to the crushed walnut shells, and omitted the chalk. The stainless steel mix accelerated the

process a bit, but I still had to clean off the parts by hand. The crushed walnut shells would still leave

an undesirable crud on the parts. Finally I took a chunk of common

canning wax compound, grated a quarter teaspoon into the media of 20%

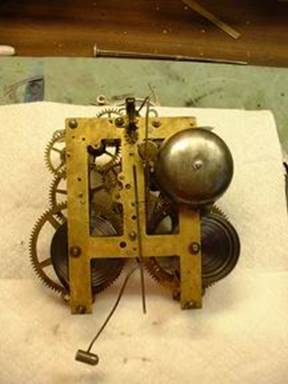

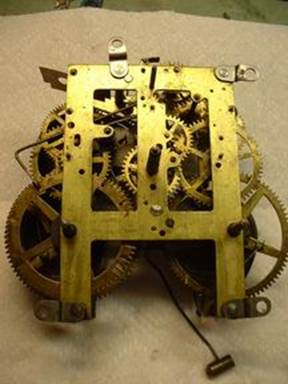

stainless steel Jeweler’s mix and 80% walnut shells. The pictures below in Step 3 show the

results after 8 hours. True, this isn’t the fastest way

to polish and clean, but it works all by itself overnight with beautiful

results. There are no “stretched”

holes from buffing, the edges of the movement remain sharp, and the parts are

clean. And a sad discovery, don’t put

distillates in a rubber lined tumbler drum.

The rubber gets soft and changes shape. I ruined the two tumbler drums in my Thumler A-R2 tumbler. Once I had liquid tight lids; now I have

leakers. They work fine for dry media,

however. (Note: since my last revision, the containers have

nearly returned to original shape and size.

I wouldn’t, however, suggest using spirits of any sort with these

rubber barrels.) I also have the new Model B

Thumler, which has a single 15-pound tumbling drum Large steel hexagon barrel

with removable rubber lining for long, efficient and quiet operation. Thumler and Grobet sell the tumbler; the

unit is marked “Grobet”, so I’ve no clue who makes it.

Sources of machines and tumbling

media are indicated below. And now for some feedback: Hi Ern, Noise can be a problem.

Being deaf helps. However, I

minimize the noise by putting the entire machine inside a large Rubbermaid

storage container (22 gallon size).

The tumbler unit rests upon a piece of carpet remnant, and the bin

rests upon a piece of carpet remnant.

In addition, the unit runs out on my back deck. Now, I generally run the tumbler at night

after I shut down the shop, so that’s also a possibility for you.

After the overnight soak and ultrasonic rinse, there is

virtually no dirt or oil present on the job.

However, the walnut shells will absorb any residue. The tumbling action will remove the patina,

fingerprints, rust and leave behind a very thin, protective layer of wax from

the grated buffing agent you introduce when charging the media mix.

Yes, although, there is so very little residue that comes

out. I always do it “just in

case”. Besides, I don’t want the oil

and wax residue to mix and cause a sludge. 4.

How fragile of a movement can you do (French)? Since my last writing, I’ve done several movements among which

were a Smith Westminster tall case movement, several American common time and

strike movements, a French crystal regulator, two anniversary clocks. I haven’t put gears and plates together

yet, though I might try. Since I

charge the tumbler drum to about 95% media mix, there is very little

opportunity for the parts to “free-fall”, moreover, when it’s running, it

sounds like a small avalanche. The

parts slide through the media rather than falling. Thus, it will take longer to tumble using

so much mix. I do not, however, run

the risk of possible fracture of count racks (the index tail) or very long

and hardened strike levers.

Yes, it’s very aromatic.

Think of gasoline. Also very

flammable. It does the job nicely. Caution around rubber and plastic. I’ve always removed hammer heads, for

example, when they have plastic tip inserts.

Leather is unaffected by the tumbling action.

It looks like anything can be tumbled. I don’t tumble clock parts except with the

request of the customer. Tumbling is

not a necessary repair step. It is

certainly not CONSERVATION. Leaving

the patina (oxide) on each piece means that oxidation is stopped. The piece is stable. If we buff off, tumble off, chemically

clean off the patina each time, eventually there will be no movement to

clean. Any removal of oxide is

actually thinning the plates and components, however miniscule. Next I plan to tumble a bezel in the tumbler, by itself. First it will be without glass, then I’ll

try one with glass.

Nope, rust, corrosion, fingerprints, blotches… they all

disappear in the ONE media mix. I

should note that stainless steel Jeweler’s Mix is rather expensive, on the

order of around $12 a pound, however, ordinary and cheaper steel mix can be

substituted if you’re not using a water based cleaner in your process. You’re welcome, Greg. 8.

Here’s a tip from Dean Sarnelle of

Once Upon A Time of Staunton, VA. Dean

introduced me to tumbling. Put the wheels on a wire through any holes that media might get

stuck in. It is also easy to pull out

of the tumbler with all the wheels at one time. I have used the same carbon steel for 17

years now. Dean Addendum: Since my last writing, I purchased a

Lortone two drum tumbler at a local tag sale.

Though I had to clean it up, oil the motor and rollers, it works like

a champ. It will be great for small

parts. Up to this point I hadn’t tried

plastic media. With this purchase

($6.00), I also got about 10 pounds of plastic pellets. So I dumped these pellets in with the

stainless steel Jeweler’s Mix, crushed walnut shells and buffing compound,

and I love the results. Most notably,

the noise level dropped. I think,

moreover, the plastic pellets acted positively as a sound dampener as well as

a good polishing media. Awesome. Commercial Sources: The

Rock Shed good source for tumblers and parts for tumblers. If you’re into rocks, he’s got the

stuff. Honest seller; he even refunded

a postal overcharge. Findingking.com (ß click link) is a first class supplier. His goods are offered on Ebay, which is

where I got a fantastic deal on the Thumler Model B large capacity machine. You can also order tumbling media, and a

multitude of shop supplies and equipment directly from his web site. His Ebay ID is findingking@fastq.com . Ebay – a great place to pick up

new tumblers Tumbling

Media (a reasonable substitute would be a few pounds of 4 penny finish

nails 1-1/4” long available by the pound --- cheap, as well as #4, #6 and #8

flat washers. They’re on Ebay, cheap) Hobby Warehouse http://www.hobby-warehouse.com/thtumobrotu.html

(current price $137.00 … a very good price) Grobet USA http://www.grobetusa.com/ (no online

catalogue) Kingsley North http://www.kingsleynorth.com/ Kramer Industries http://www.kramerindustriesonline.com/ 4 Facets http://www.4facets.com/index.html MSC Direct http://www1.mscdirect.com/eCommerce/NavigationServlet?ta=Y&N=12100017

|

|

|

||||||||||||||||||||||||||||||||||